Keeping automation systems up to date is essential in Perth’s industrial sector. Rapid technological changes mean upgrading existing systems is key to boosting productivity, reliability, and scalability. These upgrades reduce downtime, improve efficiency, and prepare businesses for future growth in an increasingly competitive market.

Why Upgrades Are Essential

Automation systems degrade over time. Aging hardware and outdated software increase the risk of failures, driving up maintenance costs and causing costly downtime. Meanwhile, business demands are changing, with faster production, stricter quality controls, and compliance pressures all requiring systems that can adapt and scale. Upgrading your automation system is the best way to address these challenges, optimise performance, and remain competitive.

Key Benefits of Automation System Upgrades

Upgrading your automation system delivers multiple advantages that directly impact your operation’s bottom line.

Improved Productivity and Precision

Modern controllers offer more accurate control over critical variables such as temperature and pressure, resulting in tighter tolerances and consistent product quality. Automation also frees staff from repetitive tasks, allowing them to focus on strategic activities that add value.

Greater Reliability and Less Downtime

Newer systems come with advanced diagnostics and remote update capabilities. Integration of AI and IoT enables predictive maintenance, reducing unplanned downtime by up to 40 percent and cutting maintenance costs by around 25 percent. This means smoother production with fewer unexpected interruptions.

Scalability and Future-Readiness

Upgraded automation solutions can grow with your business. They can now integrate with Industry 4.0 technologies like edge computing, cloud analytics, and artificial intelligence, making it easier to expand capacity without adding labour. These upgrades also improve decision-making through better data insights and ensure your system is ready for future demands.

Enhanced Operator Oversight

Centralised monitoring systems consolidate plant data and allow operators to control equipment remotely. This reduces the need for physical presence on the shop floor and enables faster responses to alarms, particularly outside normal working hours.

Partial vs Full System Upgrades

Depending on the age and condition of your system, you may choose a partial or full upgrade. Partial upgrades replace select components to reduce costs and minimise disruption. However, mixing old and new equipment can cause compatibility issues and limit improvements.

Full system upgrades are ideal when the existing system is too outdated or proprietary to integrate with modern technology. Although more costly upfront, a full upgrade maximises efficiency, reliability, and long-term adaptability.

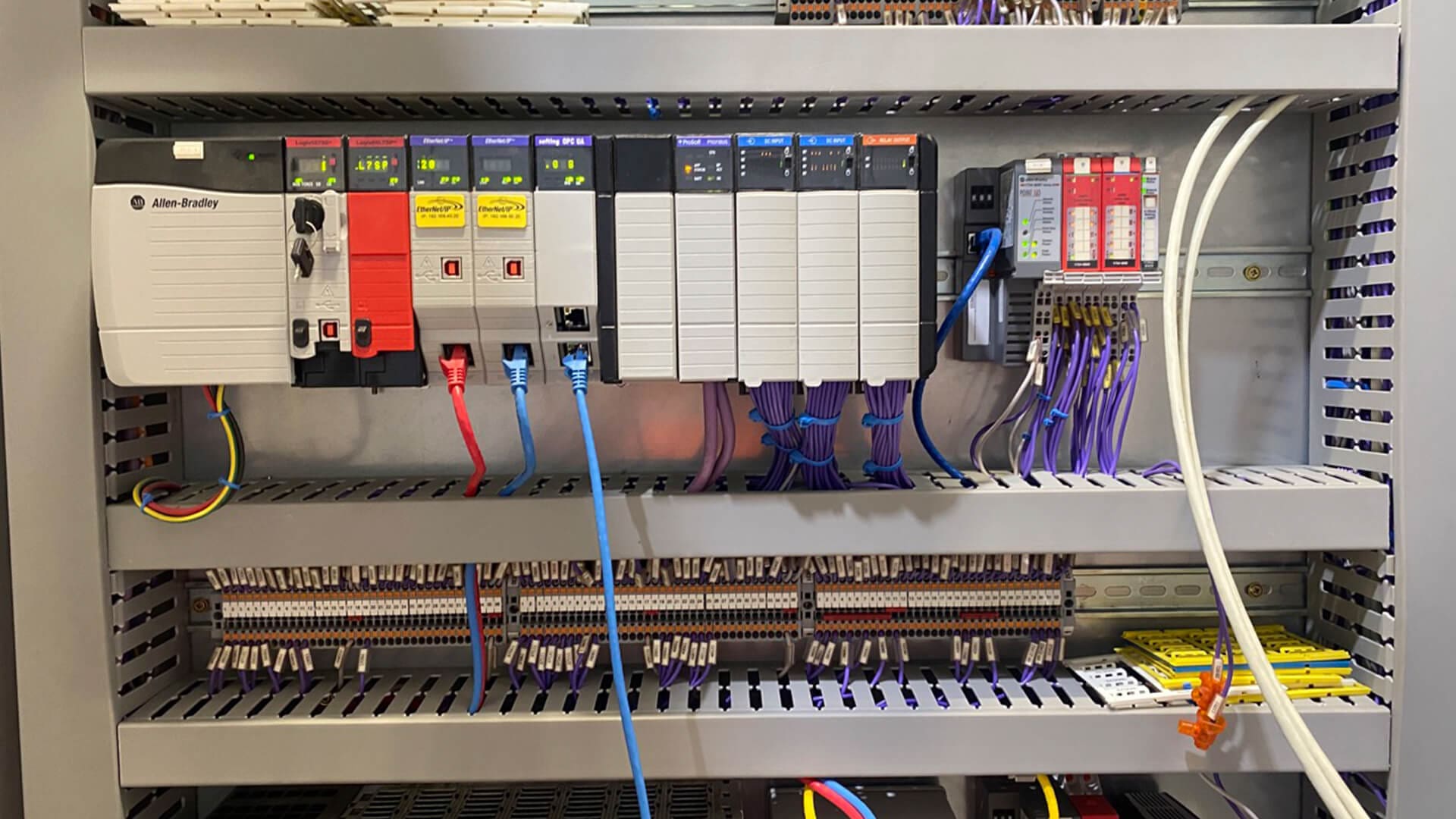

Seamless Automation Modernisation

Upgrading an industrial automation system takes specialised expertise to ensure seamless design, installation, and integration. A well planned migration strategy minimises downtime and disruption while maximising the benefits of new technology.

For Perth businesses ready to modernise, Scadalectric Automation offers tailored support to meet your unique needs. Our experienced team integrates Industry 4.0 technologies like AI-driven predictive maintenance and IoT connectivity, helping your system become more reliable and efficient. Our team doesn’t just install and upgrade systems; we also provide staff training and ongoing support to help you get the most out of your investment.

If you’re ready to improve your automation system and prepare for the future, Scadalectric Automation is the Perth expert you want by your side.