Industrial businesses are always looking for ways to boost productivity, reduce downtime, and improve product quality. One powerful tool helping them achieve this is PLC programming. Here’s a look at what PLC programming involves and how it can improve your industrial automation in Perth.

What is PLC Programming?

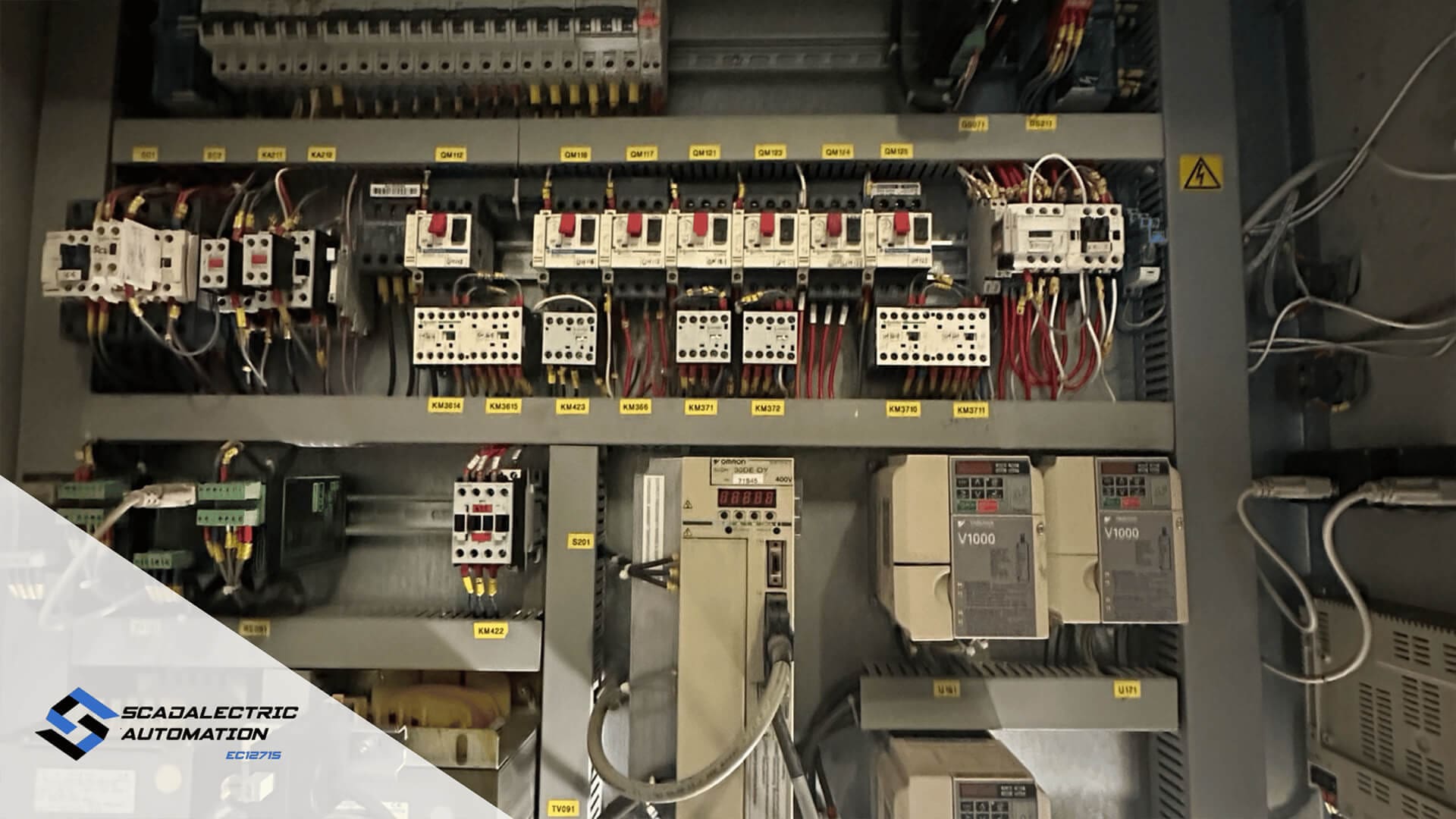

A Programmable Logic Controller (PLC) is a ruggedised, specialised computer designed for tough industrial environments. Its job is to automate processes or control machines and entire production lines by executing specific instructions tailored to your operational needs.

PLC programming is the process of creating these instructions, or control logic, which tell machines when to start, stop, or adjust based on inputs from sensors or switches. These instructions are written using graphical or textual languages and uploaded into the PLC hardware.

Simply put, PLC programming turns your machines from manual or semi-automatic systems into smart, self-regulating units capable of handling complex tasks efficiently.

How Does a PLC Work?

At its core, a PLC has a processing unit that receives input signals from sensors and devices on the production floor. These inputs can include temperature readings, pressure levels, or the detection of a product on a conveyor belt. The processing unit analyses this data based on programmed logic and sends commands to outputs like motors, valves, or alarms. When a sensor detects an issue such as overheating, the PLC can activate cooling systems or shut down equipment to prevent damage.

PLCs use Input/Output (I/O) modules to connect with machinery, which can be customised to fit the specific requirements of your setup. They also communicate with other systems like SCADA (Supervisory Control and Data Acquisition), enabling remote monitoring and seamless integration.

With Human Machine Interface (HMI) panels, operators can interact with the system in real time, adjusting settings or checking statuses. Modern PLCs support Industry 4.0 and the Industrial Internet of Things (IIoT), connecting through cloud services, web browsers, and advanced protocols to enable smarter, data-driven control.

Why PLC Programming is Vital for Perth Industries

PLCs have become essential to industrial automation in Perth for a number of reasons, including:

- Reliability and Efficiency: PLCs are solid-state devices with no moving parts, making them extremely reliable. Proper programming minimises errors and keeps production lines running smoothly.

- Flexibility: Unlike traditional hardwired control panels, PLC programming can be changed without rewiring, which is beneficial for fast changing industrial environments.

- Cost and Energy Savings: PLCs optimise equipment operation, reducing energy use and operational costs.

- Scalability: From small plants to large-scale operations, PLCs scale to meet your business needs, controlling anything from a single machine to complex production lines.

- Safety and Quality: Automated control keeps processes within safe limits, reducing risks and ensuring consistent product quality.

Choosing Expert PLC Services for Your Business

When it comes to PLC programming and industrial automation, having experienced professionals on your side is essential. Proper installation, setup, programming, and ongoing support ensure your automation system runs reliably and adapts to your industry’s unique challenges as your business grows.

With over 25 years of experience, Scadaelectric Automation is a leading choice for Perth businesses. Our deep expertise in handling both Siemens and Allen Bradley PLCs allows us to deliver customised, efficient automation solutions. From initial programming to system integration and maintenance, they offer end-to-end support that maximises operational efficiency.

Contact Scadaelectric today and take the first step toward smarter, more efficient industrial automation.